What is PEEK plastic material?

The full form of PEEK is polyether ether ketone . PEEK plastic is a semi-crystalline, thermoplastic aromatic polymer material. Because the molecular chain contains a large number of benzene rings, it has excellent rigidity, heat resistance, natural flame retardancy, and aging resistance (this is very similar to PPS to some extent). At the same time, the two ether bonds and carbonyl groups provide flexibility and excellent manufacturability to the material, which can be used as high temperature resistant structural materials and electrical insulating materials, and can be compounded with glass fibers or carbon fibers to prepare reinforcing materials. Therefore, PEEK is widely used in many fields such as electronic and electrical, aerospace, automobile, energy and other industries, medical and so on.

PEEK plastic is the material with the most excellent comprehensive properties among high-performance polymers, and is the “all-around champion” in the field of new polymer materials. PEEK is a semi-crystalline polymer material with a saturated crystallinity of 35%. One of the most prominent properties of PEEK is the wear resistance brought by the crystal. It can be seen that the crystallinity has a great influence on the performance and application of PEEK plastic, and it is an important indicator that we should pay attention to in the processing process.

Why is PEEK plastic so expensive?

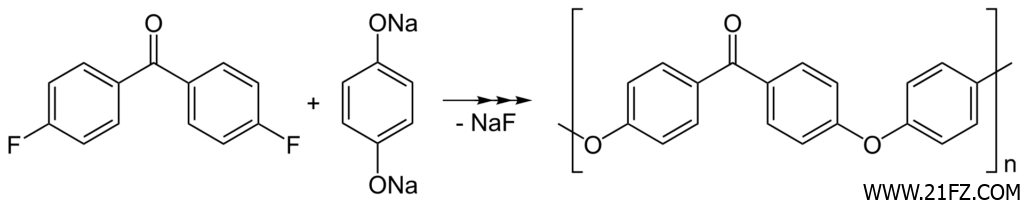

1.Expensive raw materials: The main materials required for PEEK polymerization: 4,4’-difluorobenzophenone and hydroquinone are expensive. In addition, there are relatively high requirements for the particle size and purity of the sodium salt used;

2. The reaction conditions are harsh and the cost is high: the PEEK polymerization process must ensure reaction in an oxygen-free state, and the reaction temperature is as high as 310-340°C. In order to obtain PEEK resin with higher purity, the crude product needs to be subjected to dozens of alcohol refinement processes and water washing processes;

3. High technical requirements: PEEK has good processing properties. However, because the melting point of PEEK is as high as 343°C, and PEEK has relatively strong adhesiveness. There are relatively high requirements for the material and structure of the barrel, screw, and mold of the molding equipment, as well as the temperature control of the equipment.

or you can visit this artical Why is peek plastic price so expensive?

How much does PEEK plastic cost per kilogram?

What are the properties of PEEK material?

1. The peek material is resistant to corrosion and aging.

2. The peek material has high resistance to dissolution.

3. The peek material has the conditions of high temperature, high frequency and high voltage electrical properties.

4. The peek material has strong flexibility and rigidity.

5. The peek material has more precise requirements for the size.

6. The peek material is relatively wear-resistant and has strong anti-corrosion properties.

PEEK plastic was first used in the aerospace field, replacing aluminum and other metal materials to manufacture various aircraft parts in the automotive industry because PEEK plastic has good friction resistance and mechanical properties.

As a raw material for the manufacture of engine inner covers, various components such as bearings, gaskets, seals, clutch gear rings, etc., are widely used in automobile transmission, braking and air conditioning systems.

PEEK resin is an ideal electrical insulator. It can still maintain good electrical insulation performance under harsh working conditions such as high temperature, high pressure and high humidity. Therefore, the field of electronic information has gradually become the second largest application field of PEEK plastic.

Manufacture of pipes, valves and pumps that transport ultrapure water. In the semiconductor industry, it is often used to manufacture wafer carriers, electronic insulating diaphragms and various connecting devices.

What are the applications of PEEK polymer?

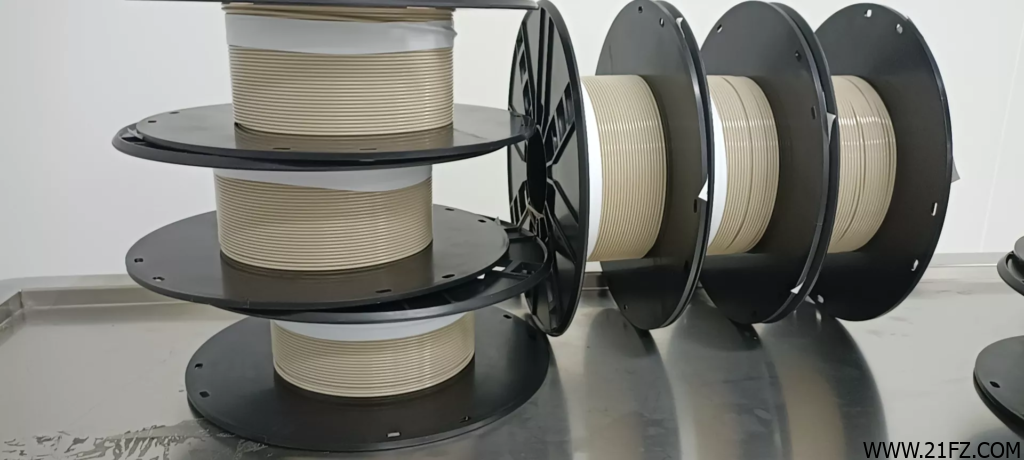

PEEK plastic material for 3D print

peek filament

Peek Tubing Material

Polyetheretherketone (Peek) for Medical Applications

peek skull

- Aerospace Industry: Peek plastic is used in the aerospace industry for parts that require high-temperature resistance, such as engine components, structural parts, and electrical components.

- Medical Industry: Peek plastic parts are used in the medical industry for applications such as dental implants, orthopedic implants, and surgical instruments. It is biocompatible, lightweight, and has excellent wear resistance.

- Automotive Industry: Peek plastic is used in the automotive industry for parts such as gears, pumps, and bearings that are subjected to high-temperature and high-stress applications.

- Electrical and Electronics: Peek plastic is used in the electrical and electronic industry for parts such as connectors, insulation, and components that require high-temperature resistance, low water absorption, and excellent dimensional stability.

- Oil and Gas Industry: Peek plastic material is used in the oil and gas industry for parts such as valve seats, seals, and connectors that require resistance to high pressure, high temperature, and corrosive environments.

Manufacturer of PEEK plastic

4 Jilin Joinature Polymer Co., Ltd. (ZYPEEK)

6 Pan Jin Zhongrun High Performance Polymer Co.,Ltd

7 Jida Evonik High Performance Polymers (Changchun) Co., Ltd.

8 Changchun Jida Special Plastic Engineering Research Co., Ltd.

Overall, Peek material applications are numerous in the industrial sector, where high-performance, lightweight, and durable materials are required.